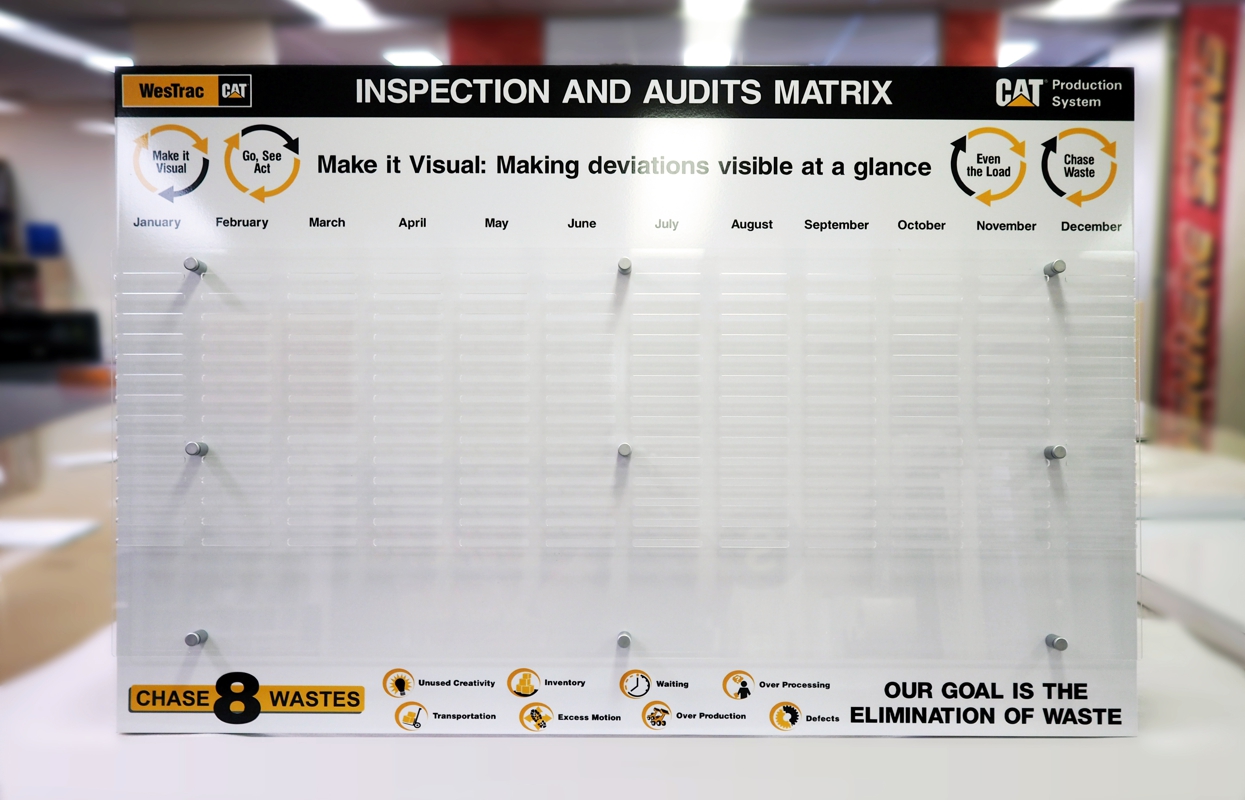

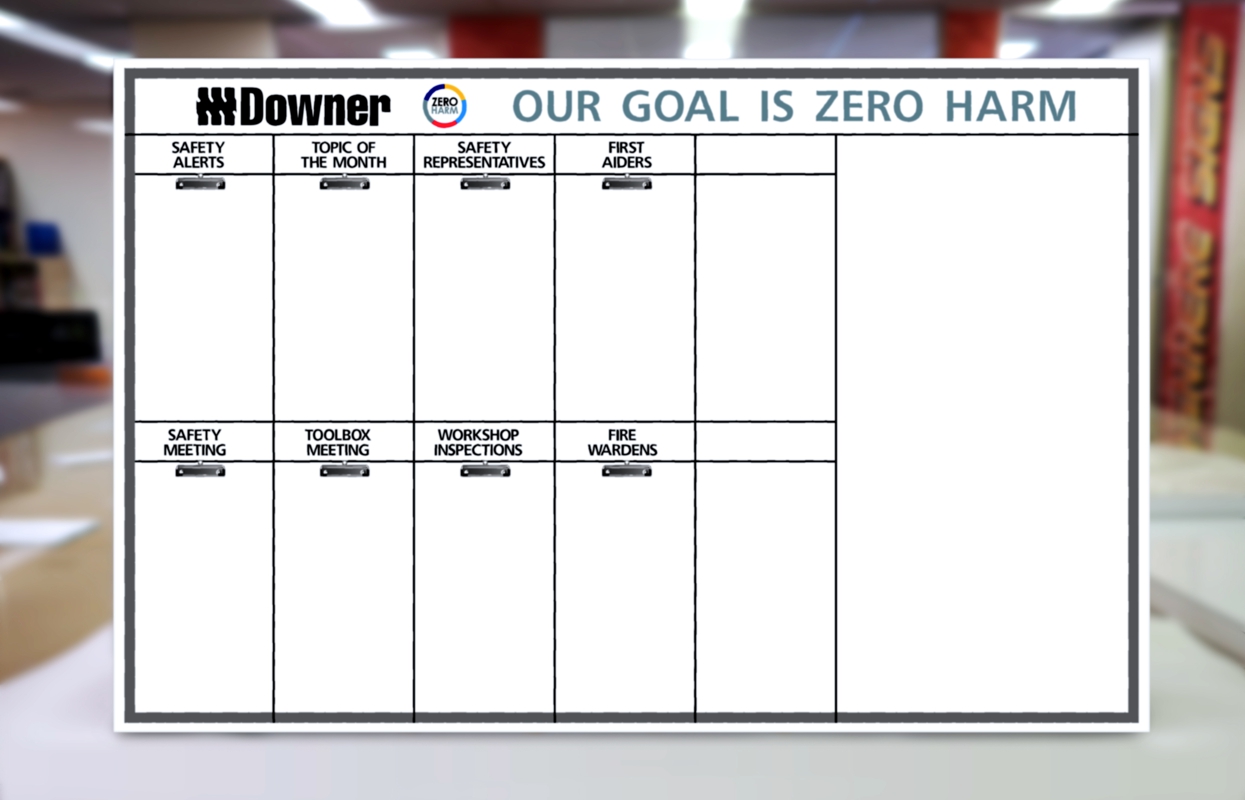

SQDC / Whiteboards

SQDC tools, whiteboards and other products for increasing efficiencies, improving safety and reducing waste at your site.

Sign Here Signs manufactures white boards and other tools that assist with implementing Lean Manufacturing and Six Sigma systems. These are popular with mining companies, and other operations, that adopt waste-minimisation practices.

We also manufacture rag bins, shadow boards and similar products that assist with keeping your site tidy and efficient. Tools can be custom made, with your branding and particular process, or we have existing products available for purchase.

Many of our clients rely on SQDC boards, and similar tools, to keep their team accountable, and to improve efficiencies within their operation. Products are manufactured for durability, which makes them an investment in your workflow.

Here’s what else you need to know.

Lean Manufacturing tools

We are able to manufacture nearly any kind of sign, white board or tool to assist you with implementing your SQDC processes. Just some of the products we make for mining companies in Perth and across WA include:

- SQDC white boards.

- Shadow boards.

- Kaizen boards.

- Value Stream Mapping (VSM) charts.

- Visual management tools.

- 5S sign solutions.

- Total Productive Maintenance (TPM) tools.

- Solutions for Kanban systems.

Manufactured in-house

All of the signs, white boards and Lean Manufacturing tools we create are manufactured in-house, in our fully equipped facility in Perth, Malaga. This enables us to keep our manufacturing costs low, and pass savings onto our clients.

It also means we can manufacture custom signage products efficiently, without compromising on quality – whether it’s a stand-alone order or a large batch of custom signage required ASAP.

Our team also includes designers, who are able to custom design SQDC tools for your operation, if you’d like your boards branded or tailored to your particular process.

Quality signs in Perth

We develop signage products that are built to last, using quality materials known for their longevity and durability. We’re also meticulous about our manufacturing process, drawing on decades of practical experience and industry knowledge.

SQDC processes are a part of everyday working life, which is why our products are capable of withstanding high levels of use. We’re committed to building hardy signs and tools that streamline your workflows.

Reliability and craftmanship go hand in hand for us. We want our clients to contact us when they need to update their existing signs because of their operation expanding or because of changes to existing processes. Not because a sign has worn out or broken because of poor craftmanship.

Benefits of Lean Manufacturing

Lean Manufacturing is a methodology for minimising waste within manufacturing systems, while also maximising productivity. Waste is considered to be anything a customer is not willing to pay for, which means they don’t see its value.

Six Sigma is similar to Lean Manufacturing, in that the methodology seeks to eliminate waste. However, Six Sigma uses a different approach, which is often used to complement Lean Manufacturing methods.

Highly successful companies, such as Toyota, Nike and John Deere, have implemented some version of these approaches, and use additional tools to map workflows, track metrics and implement ongoing improvements.

Just some of the benefits of Lean Manufacturing and Six Sigma methodologies include:

- Reduced lead times.

- Reduced operating costs.

- Increased quality of products or services.

- More efficient workflows.

- Safer sites.

- Improved accountability.

- Better responsiveness to changing demands.

Lean Six Sigma is an amalgamation of both approaches, and we are proud to be Lean Six Sigma Black Belts.

Get started

For more information on our white boards and SQDC sign solutions, please get in touch. We can develop custom products that assist with enhancing your workflows, or deliver existing stock that suits your needs.